FACILITY

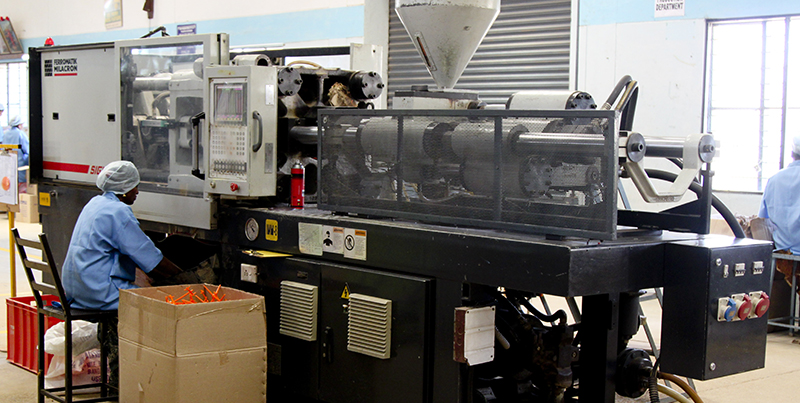

To meet the customer requirements in an efficient and effective way, IPP has set up a dedicated manufacturing facility at the KIADB, Doddabalapur Industrial Area in Bangalore, Karnataka with sophisticated and state-of-the art infrastructure. The facility is constructed keeping in mind the hygienic ambience customers prefer in today’s preconditions, and is certified by the most stringent ISO 9001 – 2015 standards.

Factory Land and Built Area – Land of approx. 95,000 sq.ft / Built Area of approx. 25,000 sq.ft.

70,000 sq.ft of land which can house factory area of up to 50,000 sq ft. is available for future expansion.

Raw Materials

IPP has the versatility and expertise in processing all of the below types of raw materials.

Plastics are classified into 3 major groups

- Commodity Plastics – Synonymous with its name ‘commodity’, it is used in our daily lives. Example – PP – Polypropylene, HDPE – High Density Polyethylene, LDPE – Low Density Polyethylene, PS – Polystyrene

- Engineering Plastics – These are substitutes for metal. Example – PC – Polycarbonate, PA – Polyamide, ABS – Acrylo Nitrile Butadiene Styrene, PA – Polyacetal, PBT – Poly Butadiene Terephatalate etc…..

- Specialty Plastics – Special purpose plastics OR alloys (blending of two different Polymers) to achieve a specific application

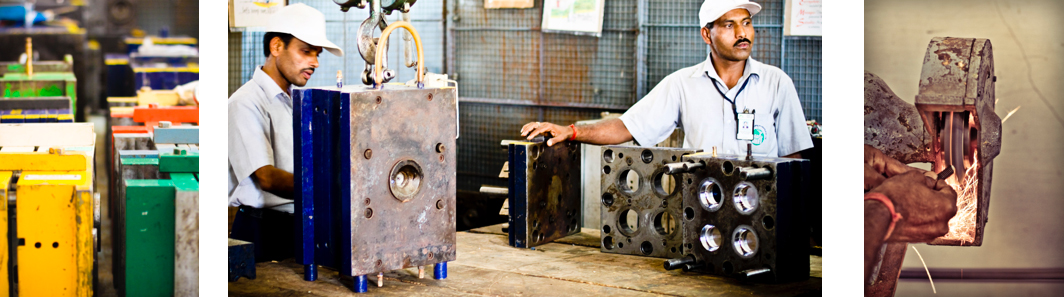

TOOL ROOM

The Company has a Tool Room comprising of Lathe, Drilling and Grinding facilities. For more comprehensive requirements, IPP has tied up with the most sophisticated 3rd party tool room’s in Bangalore.

The Tool Room has systems that are integrated with CAD facility. The software’s primarily used for designing are “pro – e” & “catia“, both high end designing software’s.

Quality COntrol

At IPP, Quality is paramount. All incoming materials are inspected prior to processing. Post molded components are also subjected to vigorous test before shipping the material to customers. The company lab is well equipped with all latest and required quality control facilities.

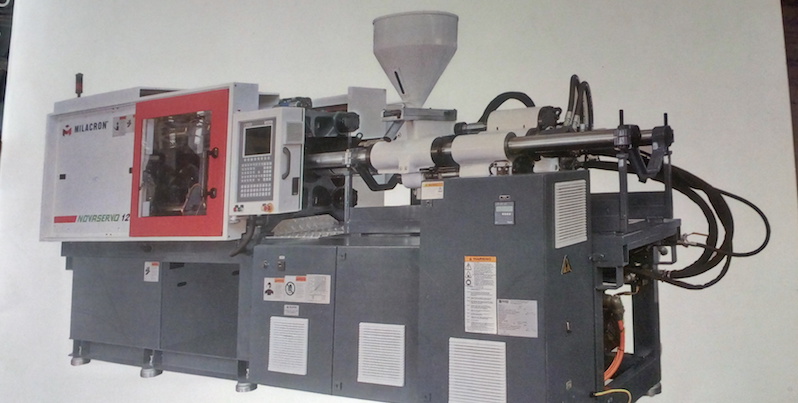

MACHINERY LIST